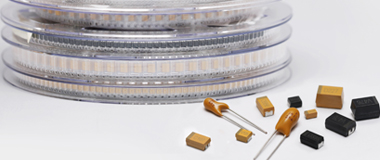

WEE Technology Company Limited - WEE are Capacitors Specialist

WEET is glad to inform all the customers that we are able to provide a wide range of Resistor, which including Carbon Film Resistor, Metal Film Precision Resistor, Metal Oxide Resistor, Fusible Resistor, Wire Wound Resistor, High Precision Metal Film Leaded Resistor,Cement Resistor, Ceramic Resistors, Non-Flammable Wire-Wound Power Resistor. Check more details at our website : https://www.weetcap.com/Resistors/

WEET Hot Resistor Product List:

WEET CR Sereis Carbon Film Resistor

WEET MF Series Metal Film Precision Resistor

WEET MO Series Metal Oxide Resistor

WEET KNP KNS Series Wire Wound Resistor

WEET FR Series Fusible Resistor

WEET SQM Series Radial Cement Ceramic Resistor

WEET SQP Series Axial Cement Ceramic Resistor

WEET SQZ Series Cement Ceramic Resistor

WEET Hot Resistor Product Introduction and Applications, Classification of Fixed Resistors:

1. Metal film resistors

Metal film resistor is one of the film resistors. It adopts high-temperature vacuum coating technology to closely attach nickel chromium or similar alloy to the surface of porcelain rod to form a film, cut and adjust the resistance value to achieve the final required precision resistance value, then add appropriate joint cutting, and coat its surface with epoxy resin for sealing protection

Metal film resistance is a widely used resistance so far. It has high precision, stable performance, simple and lightweight structure. It plays an important role in the electronic industry and military aerospace under the requirements of high precision

2. Carbon film resistors

Carbon film resistor is also one of the film resistors. It is made by using high-temperature vacuum coating technology to tightly attach carbon to the surface of porcelain rod to form carbon film, then add appropriate joint cutting, and coat its surface with epoxy resin for sealing protection. Its surface is often painted with green protective paint. The thickness of the carbon film determines the resistance value, and the resistor is usually controlled by controlling the thickness of the film and grooving

Carbon film resistors are widely used in electronics, electrical appliances and information products, with the cheapest price, stable quality and high reliability

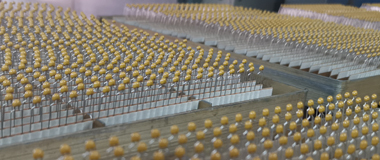

3. Wire wound resistors

Wire wound resistor is a kind of fixed resistance. The wire wound resistor is formed by winding the resistance wire on the insulating framework. Resistance wires are generally made of nickel chromium, manganese copper and other alloys with certain resistivity. The insulating skeleton is made of ceramic, plastic, metal coated with insulating layer and other materials into various shapes such as tube shape, flat shape and so on. The resistance wire can be wound one layer or multiple layers on the skeleton according to the needs, or the non inductive winding method can be adopted

Winding resistance is mainly used for voltage division, voltage reduction, shunt and load resistance in AC and DC circuits such as precision instruments, telecommunications instruments and electronic equipment

4. Cement ceramic resistors

Cement resistor is made by winding the resistance wire on alkali free heat-resistant porcelain, adding heat-resistant, moisture-resistant and corrosion-resistant materials to protect and fix it, putting the winding resistance body into a square porcelain frame and filling and sealing it with special non combustible heat-resistant cement. The outer side of cement resistance is mainly made of ceramic

Cement resistor has the characteristics of large overall size, shock resistance, moisture resistance, heat resistance, good heat dissipation and low price. It is widely used in power adapter, audio equipment, audio frequency divider, instruments, meters, television, automobile and other equipment