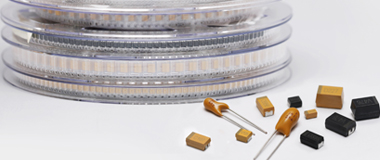

High voltage ceramic capacitor is a kind of ceramic capacitor, which is made by extruding high dielectric constant ceramics (barium titanate titanium oxide) into circular tubes, discs or disks as the medium, coating metal films (usually silver) and sintering at high temperature to form electrodes, using tinned copper clad steel leads, coated with protective enamel on the outside, or wrapped with epoxy resin. The shape is blue disc. Generally, high-voltage ceramic capacitors are used in power systems, such as power system metering, energy storage, voltage distribution and other products.

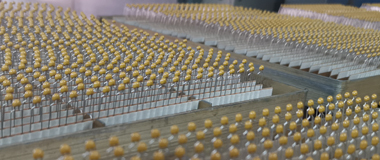

In recent years, with the development and progress of science and technology, the development of high-voltage ceramic capacitors has made considerable progress and has been widely used. High voltage ceramic capacitors have become one of the indispensable components of high-power high-voltage electronic products.

High voltage ceramic capacitors have the following advantages:

1. High voltage resistance, low loss

2. Good frequency characteristics and high stability

3. The special series structure is suitable for the long-term working reliability of high-voltage poles

4. High current climbing rate and applicable to non inductive structure of high current loop

5. High insulation resistance, long service life

According to the above advantages, high-voltage ceramic capacitors are used in highly stable oscillation circuits as circuit capacitors and padding capacitors. And its main function is to remove high-frequency interference, so it is very suitable for negative ion products, such as lasers, X-ray machines, control and measurement equipment, igniters, transformers, electrical equipment, electrostatic spraying and other electromechanical equipment requiring high voltage and high frequency.