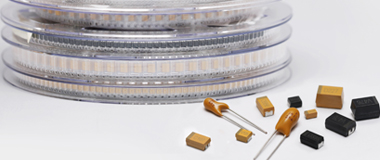

Composition of Tantalum Chip Capacitors

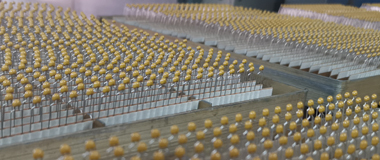

Like other electrolytic capacitors, the chip tantalum capacitor is composed of anode, some electrolytes and cathode. The anode is isolated from the cathode, so only a very small leakage DC current can flow through the capacitor. The anode is made of pure tantalum metal. The metal is ground into fine powder and sintered into particles at high temperature. This forms a very porous anode with a high surface area. The high surface area is directly converted into an increased capacitance value.

The anode is then covered with a layer of insulating oxide, which is used as a dielectric. This process is called anodizing. This step must be precisely controlled to reduce the tolerance and ensure the correct capacitance value, because the degree of oxide growth determines the dielectric thickness.

In the case of solid chip tantalum capacitors, electrolytes are added to the anode through pyrolysis. The tantalum capacitor of the solid patch is then immersed in a special solution and baked in an oven to produce a manganese dioxide coating. This process is repeated until a thick coating is present on all internal and external surfaces of the particles. Finally, the particles used in the solid chip tantalum capacitor are immersed in graphite and silver to provide a good cathode connection. Compared with solid tantalum chip capacitors, wet tantalum chip capacitors use liquid electrolytes. After the dielectric layer is grown, it is immersed in a liquid electrolyte in the shell. The shell and electrolyte are used together as the cathode in wet chip tantalum capacitors

Application of Chip Tantalum Capacitor

Applications using SMD tantalum capacitors utilize its low leakage current, high capacity, and long-term stability and reliability. For example, they are used for sample and hold circuits, which rely on low leakage currents to achieve long hold durations. They are also commonly used for power filtering on computer motherboards and mobile phones because of their small size and long-term stability, usually in the form of surface mounting. SMD tantalum capacitors are also available in military versions to provide tighter tolerances and wider operating temperature ranges. They are popular alternatives to aluminum electrolytes in military applications because they do not dry out and change capacitance over time. Medical electronic products also rely on tantalum chip capacitors for their high stability.