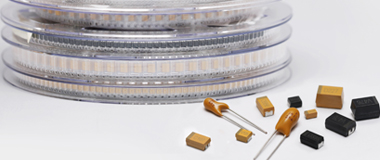

As a kind of electrolytic capacitors, SMD tantalum capacitors are widely used in various electronic products, especially those with high-density assembly and small internal space, such as mobile phones, portable printers, etc.

The chip tantalum capacitor uses tantalum (Ta) as the anode material. According to the different anode structures, it can be divided into foil type and tantalum sintered powder bonded type.

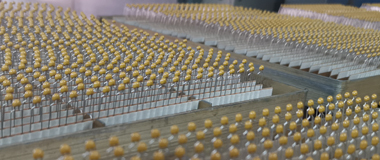

Product introduction In tantalum powder sintered tantalum capacitors, due to different working electrolytes, they can be divided into solid tantalum capacitors and non solid tantalum capacitors.

Among them, the consumption of solid tantalum electrolytic capacitor is the largest. Because tantalum capacitors use metal tantalum as the medium, they do not need to use electrolyte like ordinary electrolytic capacitors.

In addition, the tantalum chip capacitor does not need to be fired with aluminum coated capacitor paper like ordinary electrolytic capacitors, so it has almost no inductance, but also limits its capacity.

Advantages Analysis of WEE Technology CA45 CA45L CA55 Tantalum Chip Capacitor

1. Small volume

2. Wide temperature range and high temperature resistance

3. Long service life, high insulation resistance and low leakage current

4. Small capacity error

5. Small equivalent series resistance (ESR), good high-frequency performance

Disadvantages Analysis of WEE Technology CA45 CA45L CA55 Tantalum Chip Capacitor

1. The withstand voltage is not high enough

2. Low current

3. High price

The full name of the chip tantalum capacitor is tantalum electrolytic capacitor, which is also a kind of electrolytic capacitor. Since the tantalum oxide is used as the medium, it does not need to use electrolyte like ordinary electrolytic capacitors. In addition, unlike ordinary electrolytic capacitors, tantalum capacitors are fired with aluminum coated capacitor paper,

So it has almost no inductance, but it also limits its capacity. In addition, there is no electrolyte inside the chip tantalum capacitor, which is very suitable for working at high temperatures.

Although the chip tantalum capacitor is characterized by long service life, high temperature resistance, high accuracy, and excellent high-frequency ripple filtering performance, it has smaller capacity, is more expensive than aluminum capacitors, and is relatively weak in voltage and current resistance.

The reasons for the explosion of the tantalum electrolytic capacitor on the chip can be roughly divided into two cases: the explosion caused by the use of reversed positive and negative poles, the explosion caused by the high AC ripple in the circuit, and the explosion caused by the excessive peak output current of the circuit when the use voltage is appropriate.

Some customers who do not understand the withstand voltage may easily cause the breakdown of the tantalum electrolytic capacitor on the chip, which may be burnt or burst. Customers are expected to refer to the user manual before using the chip tantalum capacitor. Generally, the chip tantalum capacitor will not explode. Please rest assured that you can use it!